Equipment layout

Equipment layout

Equipment layout

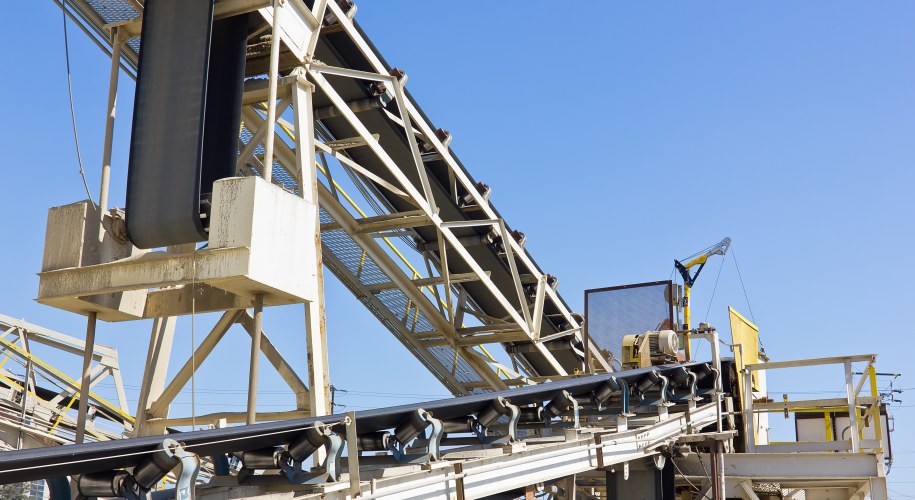

- development of installation concepts for new and existing plants

- preparation of tender documents, comparison of offers and evaluation

- detailed installation layout of equipment with all machines, conveyor paths, platforms, catwalks, etc.

- checking of supplier drawings

- preparation of complete documentation

Piping design

Piping design

Piping design

- measurement of existing plants, 3D laserscan

- development of pipeline concepts

- creation of process flow diagrams (PFD, P&ID)

- preparation of pipe classes according to various standards

- detailed engineering of pipelines with fittings, installation parts, supports and secondary steel construction

- creation of parts lists, material excerpts and tenders with support up to award of contract

- supervision of construction sites, site management/coordination

Specialisation

Specialisation

Specialisation

- database-based "intelligent" flow diagrams R+I/PFD/P&ID

- create and apply pipe classes DIN/EN/ASME/Hygiene/Food

- 3D laser scan for as-built plans and as a planning environment

- consistent data from P&ID to 3D model to parts list

- expansion of existing plants from concept to execution

- direct line to all engineering departments in our office

Focus: Planning in existing environment

Focus: Planning in existing environment

Focus: Planning in existing environment

Planning in spatially limited existing environments is always a special challenge. Experienced, qualified specialist engineers, close coordination with the other engineering departments directly in house and the use of state-of-the-art planning tools enable IPRO to master these challenges with high quality and adherence to schedules. Thus, 3D planning takes place directly in the integrated 3D point cloud of the existing building. Regular meetings via video conferences with joint viewing of the 3D model guarantee close involvement of the client's project team including operators and maintenance staff.